CE Marking (Europe)

To place a CE Mark on electrical products to be legally sold on the European Market, a manufacturer has to be able to demonstrate compliance with the applicable EU regulations and directives including:

To place a CE Mark on electrical products to be legally sold on the European Market, a manufacturer has to be able to demonstrate compliance with the applicable EU regulations and directives including:

- Low Voltage Directive (LVD) 2014/35/EU;

- Machinery Directive 2006/42/EC;

- Medical Devices Directive (MDD) 93/42/EEC;

- Toys Directive

- Pressure Equipment Directive

- Personal Protective Equipment Regulation

- Construction Product Regulation

ATEX CERTIFICATION

European ATEX Directive 2014/34/EU

Electrical and non-electrical equipment for use in workplaces potentially at risk for explosive atmospheres must ensure a level of safety appropriate to the area of installation.

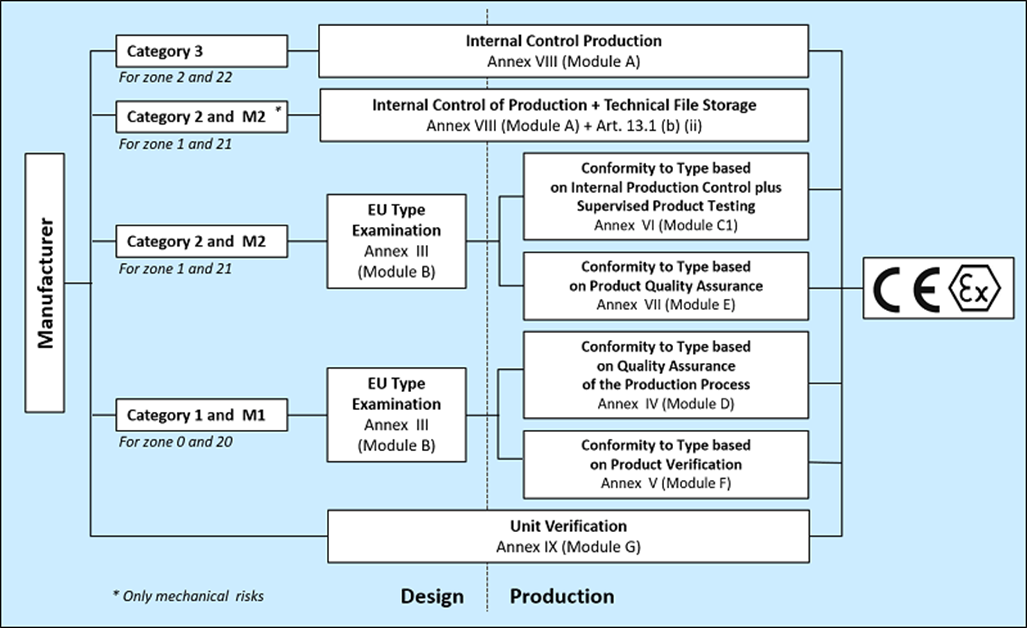

In Europe this is enforced through the ATEX Directive 2014/34/EU. In addition to CE Marking, equipment used in explosive atmospheres must also gain the Ex Mark which requires in most cases accredited testing, Notified Body approvals.

Products included in the scope of the ATEX Directive 2014/34/EU include:

There are three steps to being able to gain ATEX certification from an ATEX Notified Body:

- Preparation of a risk analysis, technical documentation, definition of intended use, technical calculations, drawings, product description

- Compliance with one or several type of protections or product standards

- Compliance with the ATEX directive for products used in explosive atmosphere

How we can help

The design requirements for products used in an explosive atmosphere differ significantly from those employed in a non-explosive atmosphere. Furthermore, there are key design differences depending on which type of explosive atmosphere they may be used in. It is therefore imperative to understand the what the design implications are at the start of the product design process.

We can help you at each step of the ATEX compliance process to ensure that the correct assumptions and decisions have been made, test your products, provide you with the appropriate certifications, and perform a quality assessment of your place of manufacturing or supplier.

Notified Bodies

QVC through its alliance partner Notified Bodies is offering ATEX certification to customers.

Our laboratories offer ATEX testing for the following types of products and protection methods: